About Us

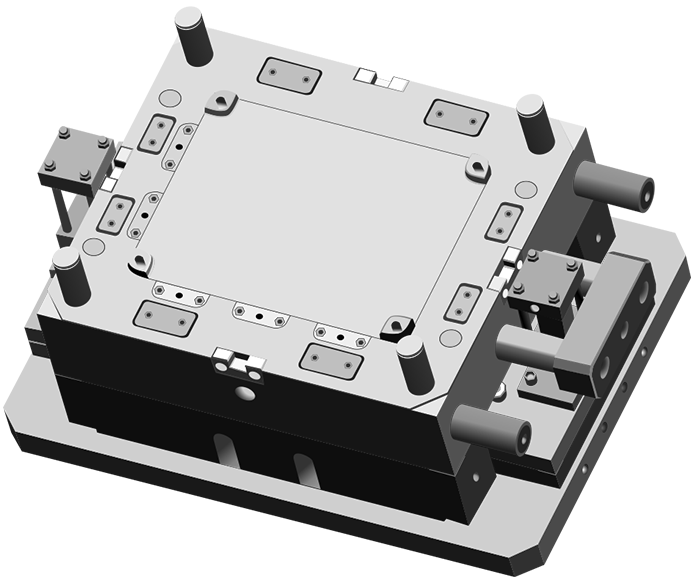

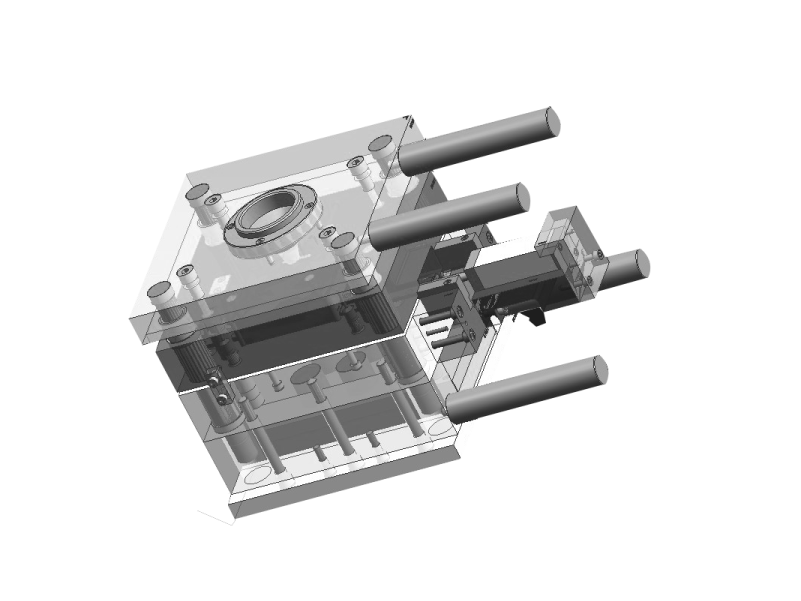

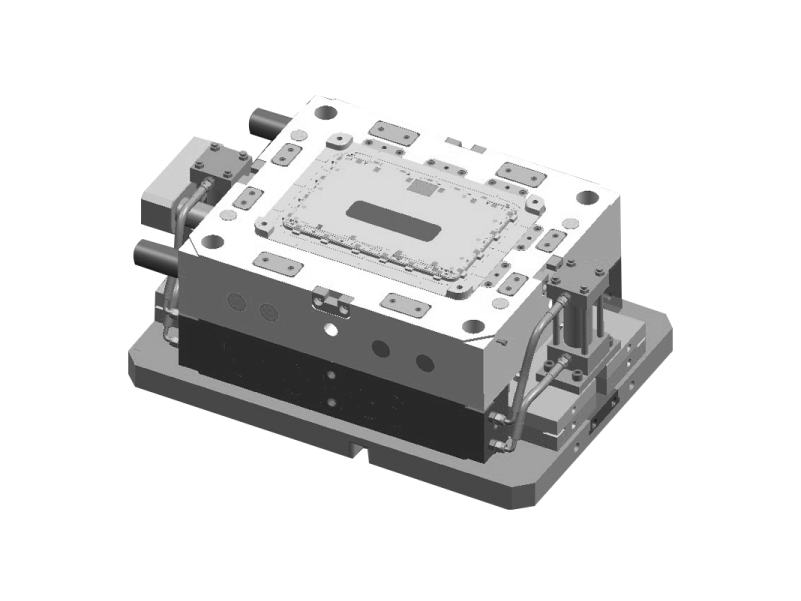

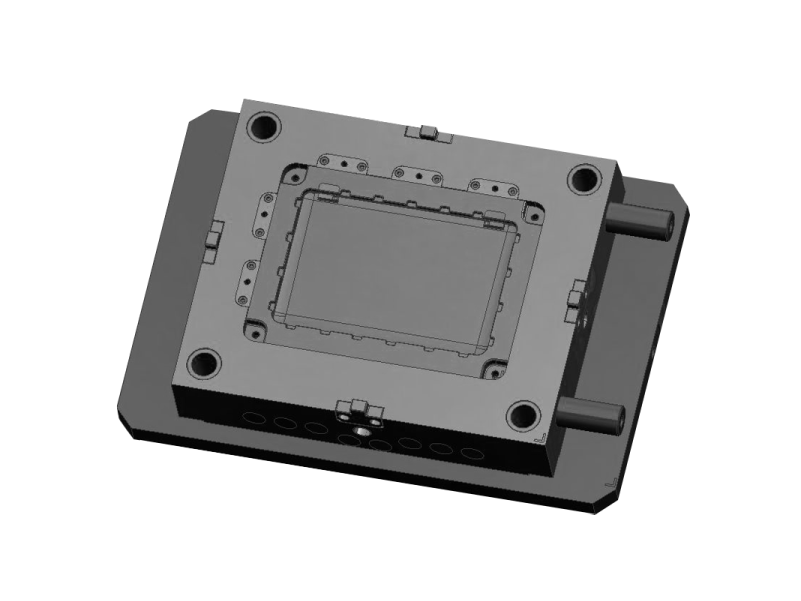

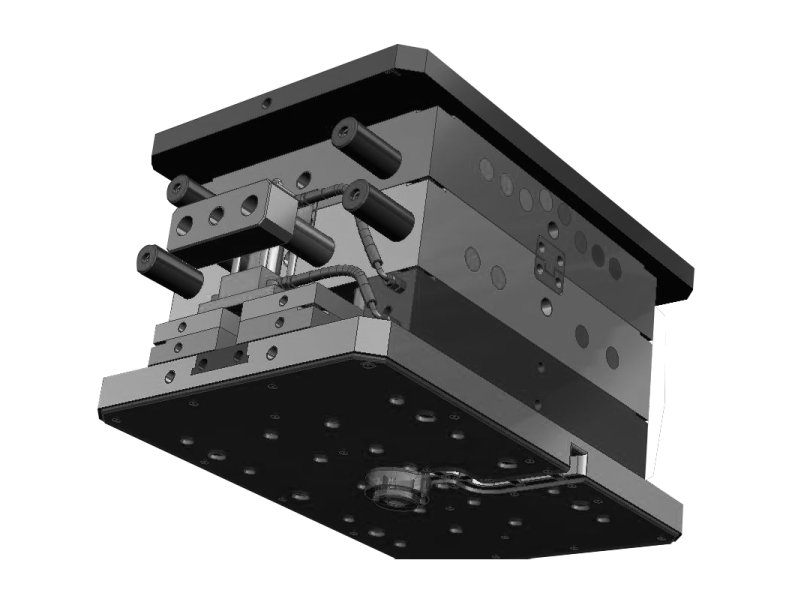

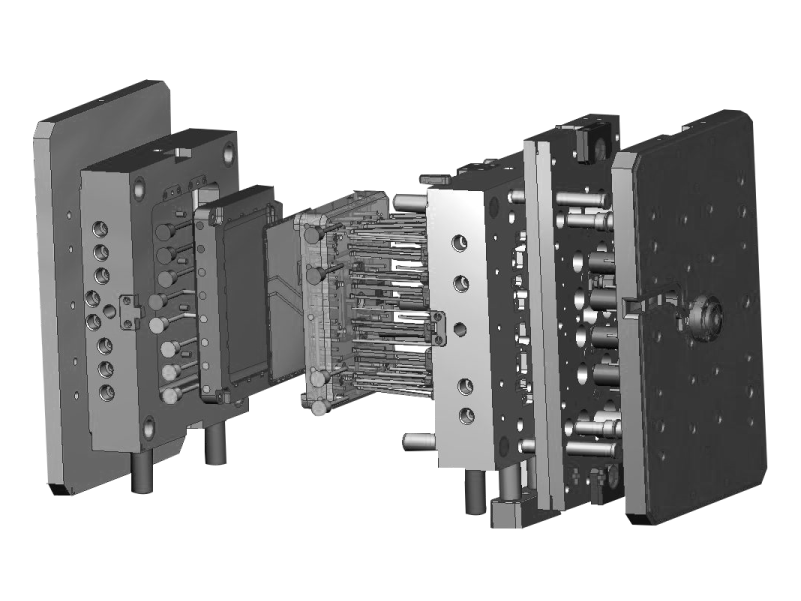

PRECISION PLASTIC INJECTION MOULD

Motivation is what gets you started. Habit is what keeps you going. We strongly believe that design can make a huge difference to our life and are making every endeavor to create products with greatest integration of design and technology.

To meet our target of Creating As Art and to give you the best service and product, we have expanded our team to have fully control over all the product development processes. We are keeping a close eye on each process and each detail to ensure each tiny part and each component is done and fine tuned in the best way.

As a professional moulding supplier, we have been in the plastic injection mould business for more than 15 years, and are offering manufacturing services to make plastic injection mould, plastic parts injection, surface painting and also product assembly for almost all kinds of electronic products.

Keeping doing what we promise and keep learning what can not do now has given us more and more opportunities to stay competitive in the industry. We are proudly supported by clients all over the world, and are still making every endeavor to bring amazing and brilliant work to our clients.

Why Work With Us

PROFICIENT SKILLS AND SERVICES

We believe in our manufacturing service and hold ourselves to higher standards. We truly care about each detail even from sketching. Working with us will let you feel easier and save a lot of your time, energy and cost.

PRODUCT DESIGN

PRECISION MOULDING

PLASTIC INJECTION

Fine-tune Each Detail With Smart Mind

with best quality & at competitive cost

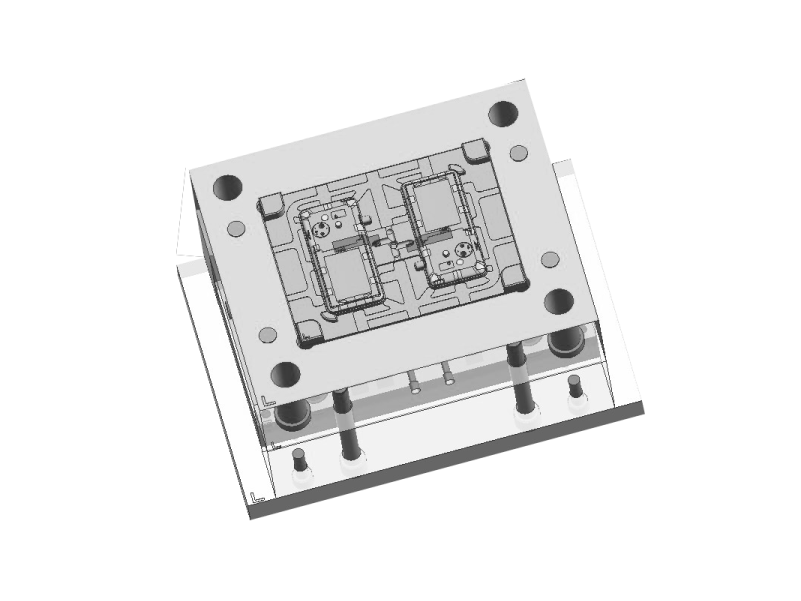

Mould Design

FROM SKETCHES TO MECHANICAL DRAWINGS

THE FIRST AND ALSO ONE OF THE VERY MOST IMPORTANT STEPS IN PRODUCT REALIZATION.

Good designs save time, save material, save work and save cost. To design a product requires a lot more work than to produce one. Too many factors need to taken into account to get a perfect product design. After the design is done, a systematic processes of tests have to be adopted to make it approved for next step such as mold flow analysis.

Recent Work

CONCEPT DESIGN • 2D DRAWINGS • 3D DRAWINGS

High Precision Moulding

FROM VERY SIMPLE TO VERY COMPLICATED PROJECTS

We are fully equipped with the most advanced precision plastic injection mould machines to make the proud products for your specific projects. No matter it is a small and simple project or a big and complicated one, we will welcome it with open arms and handle it with good care.

Advanced EDM

Over 6 sets of imported EDM machines and some others.

Advanced CNC

Over 5 sets of imported CNC machines.

Drilling & Grinding

Over 15 sets of imported machines plus dozens of others.

Awesome Projects

IN MANY FIELDS TODAY

We have done so many successful projects from many fields including consumer electronics, home appliance, transportation, medical, security, automobile, office, industrial, jewelry, accessories and many more others.

High Efficiency Production

PLUS DOUBLE COLORED INJECTION MACHINE

In order to meet our clients’ requirement of fast delivery, we have got ready more than 50 sets of injection machine ranging from 200T to 1400T. Besides the regular injection machines, there are also a couple of double colored injection machines. Our high work efficiency will boost your business with no doubt.

HIGH EFFICIENCY

LOW COST

QUICK DELIVERY

Expert Design Advice

RICH EXPERIENCE FROM MANY FIELDS

Connect.

SOCIAL PRESENCE

Find Us.

ADDRESS

#1, Shimei Dongfu Street,

Dongguan, Guangdong, China

Let’s Work Together

CONTACT US TODAY

Contact us here for any technical consultancy of precision plastic injection mould, project evaluation, free design and any inquiry or question about our products and services. Just email us here.